She Keeps Things Moving

She Keeps Things Moving

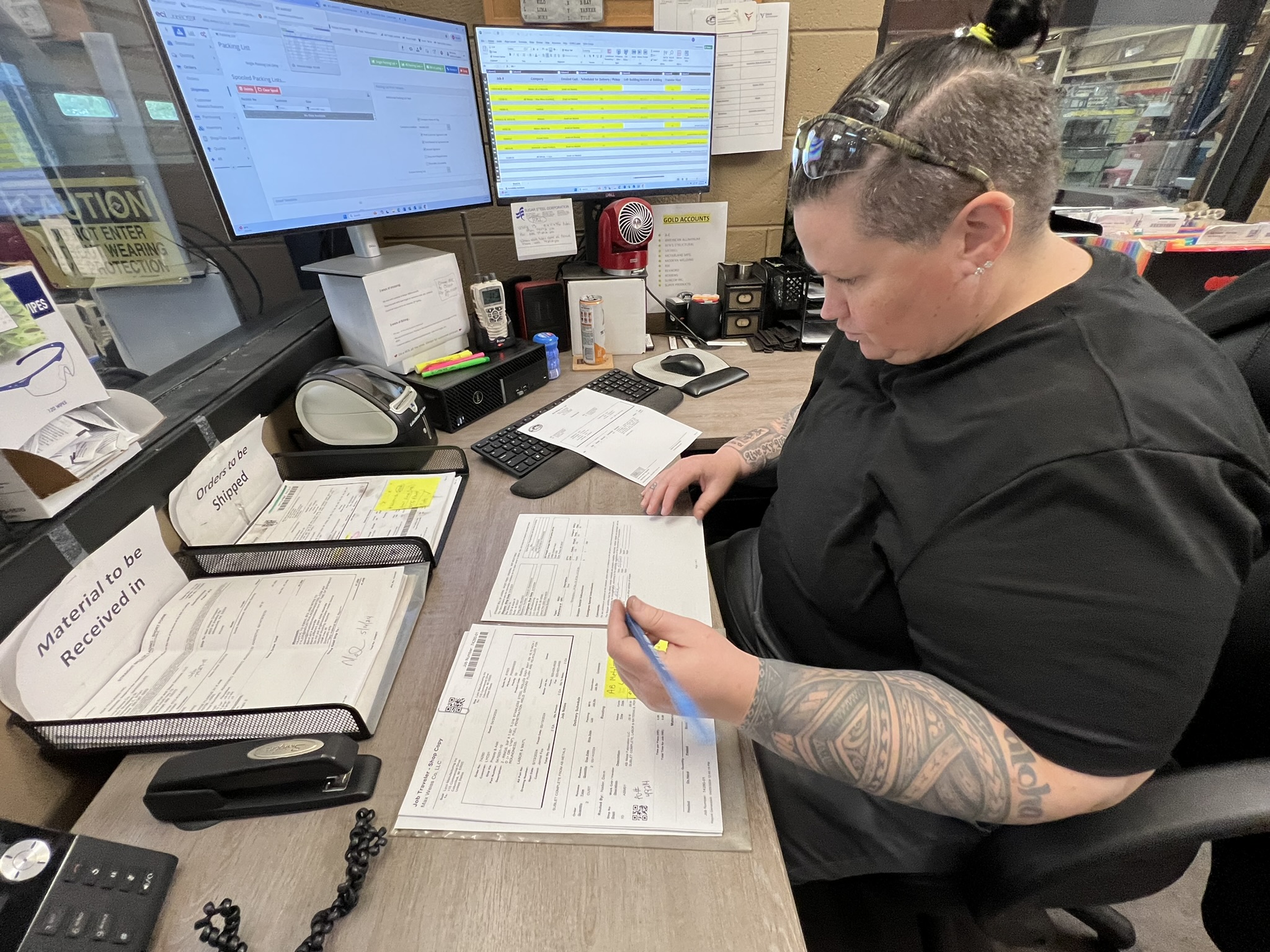

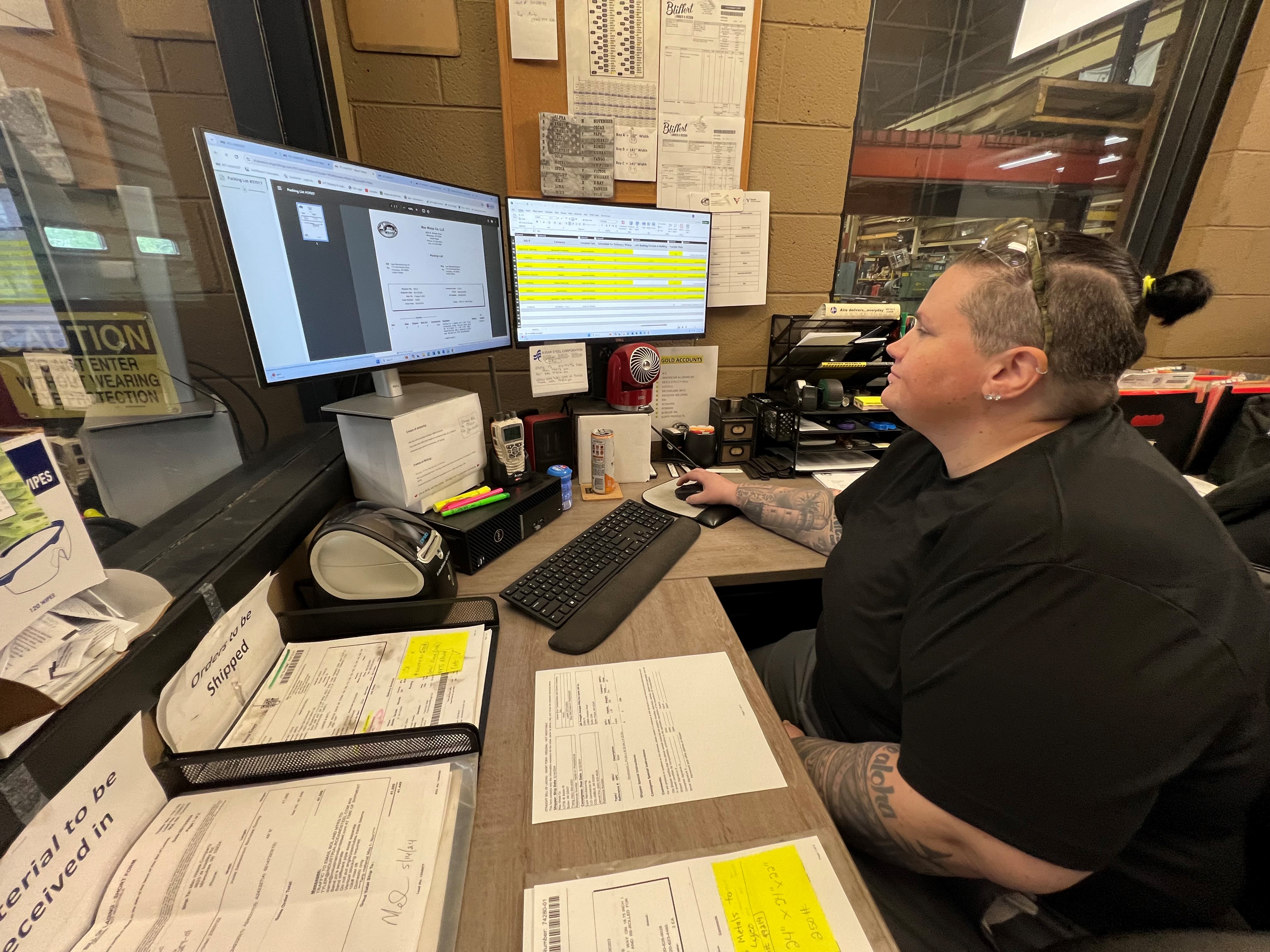

Melissa Kabacinski went from rolling metal to rolling trucks.

She makes it look easy, too … even on the days where, she admits, things get a bit hectic.

Melissa is our new Logistics Coordinator, a role she more or less trained for running a metal rolling and forming machine for nine years on our shop floor.

She learned every facet of job orders. Being naturally detail-oriented, Melissa absorbed every step of our production processes. Things don’t start until materials are delivered. They end when finished products ship out.

She learned every facet of job orders. Being naturally detail-oriented, Melissa absorbed every step of our production processes. Things don’t start until materials are delivered. They end when finished products ship out.

By overseeing all these deliveries and shipments, Melissa is the alpha and omega of getting things done. She’s responsible for the starting and finishing gates. Absent her diligence, our metal bending and metal fabrication work would be in a state of perpetual limbo.

Every day is different. There might be two shipments and deliveries … or 20. Either way, Melissa has to ensure that raw materials get to the right production station, and completed work on its way to the customer.

In between, she’s scheduling future arrivals and shipments. It’s a lot of tracking, and coordination, and minimizing overlap and disruption. Her phone rings a lot. The paperwork never slows.

Good thing she understands production. Melissa’s a veteran of the manufacturing world. Prior to joining Max Weiss Company, she worked at a cold rolled and formed steel manufacturer, and a plastics company. She’s a graduate of Moraine Park Technical College in Fond du Lac, Wis., and St. Francis High School in St. Francis, a Milwaukee suburb.

Good thing she understands production. Melissa’s a veteran of the manufacturing world. Prior to joining Max Weiss Company, she worked at a cold rolled and formed steel manufacturer, and a plastics company. She’s a graduate of Moraine Park Technical College in Fond du Lac, Wis., and St. Francis High School in St. Francis, a Milwaukee suburb.

Melissa’s only learning curve as Logistics Coordinator were some office tasks. They didn’t take long. Who has time? With all the moving (literally) parts she supervises, there’s little wiggle room for non-comprehension.

We’re fortunate that Melissa likes detail work. Many would be overwhelmed by so many different responsibilities at once. She just rolls with it – just like she’s been rolling with us, in one form or another, for nearly a decade.

<<-- Back to News Email to a friend