Testing the Bend … and Not Just for Kicks!

“Spec buildings” are common in the world of construction.

“Spec buildings” are common in the world of construction.

Developers routinely build structures without a committed tenant for the space. They know the dimensions and building features needed by various industries. They construct accordingly … and trust a tenant will come along.

“Spec bending?” This might be a new one in the world of metal forming and metal rolling.

Would anyone really invest in test-forming pricey metal pieces, for a project that might or might come to fruition? Who would do such a thing?

Your friendly metal-bending maniacs at Max Weiss Company, that’s who!

A new Midwest soccer stadium project will be bidding soon. Having helped build numerous stadiums and arenas across the U.S., we’re naturally interested. We’ve proven the chops to kick these projects through the goal (metaphorically speaking).

This potential project posed a quandary, though. Some of its details are known. One wild card was the size of its steel beams, and their forming requirements. Simply put, we’d never bent such large pieces to so tight a radius.

We had to know – thus, our first foray into “spec bending.” The result showed that yes, our people and equipment are up to the task (not that we’re surprised)!

We had to know – thus, our first foray into “spec bending.” The result showed that yes, our people and equipment are up to the task (not that we’re surprised)!

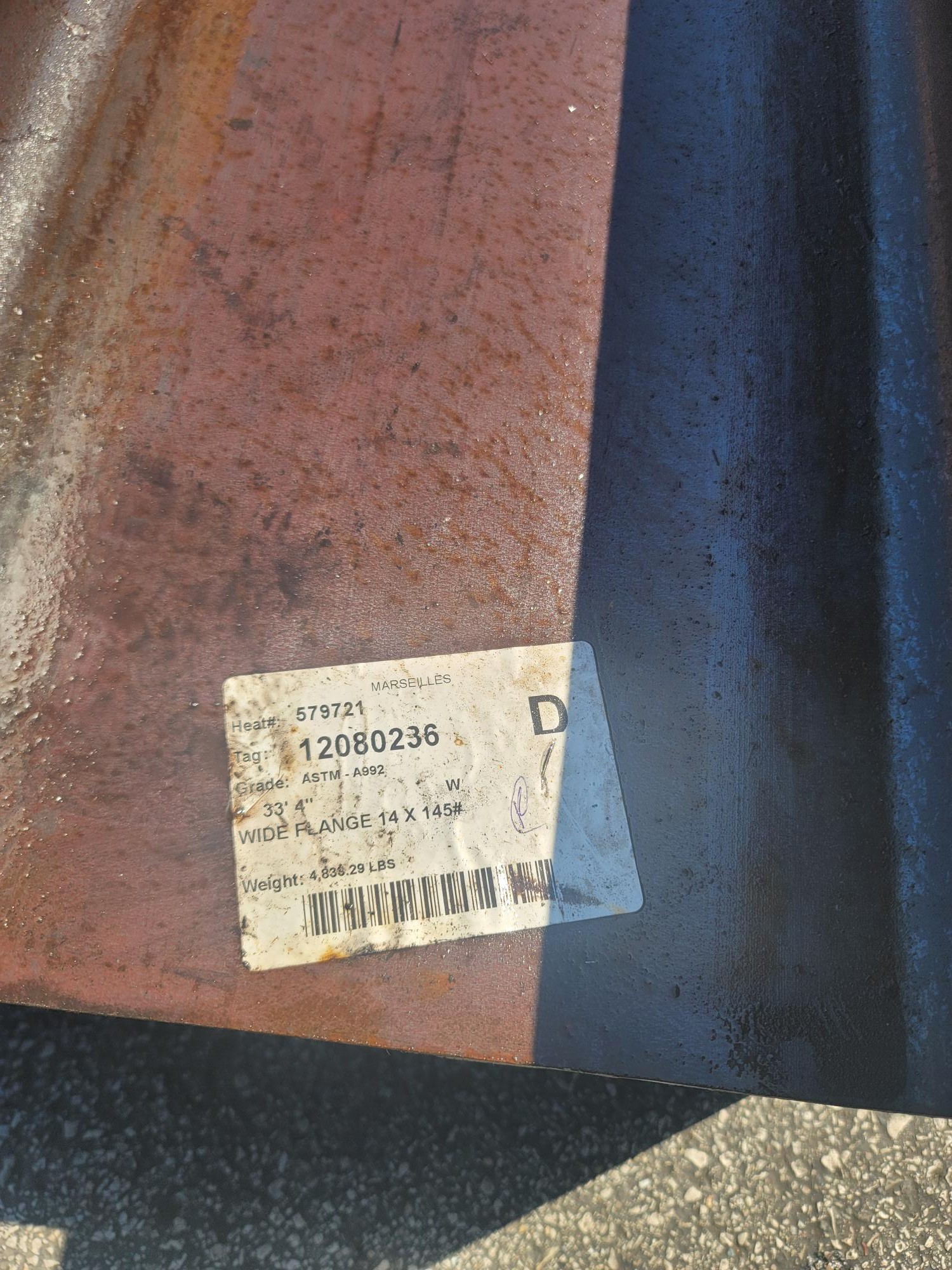

We invested several thousand dollars to purchase a 33’4” long wide flange beam. Our most senior production employee, Phil Steinke, stepped up.

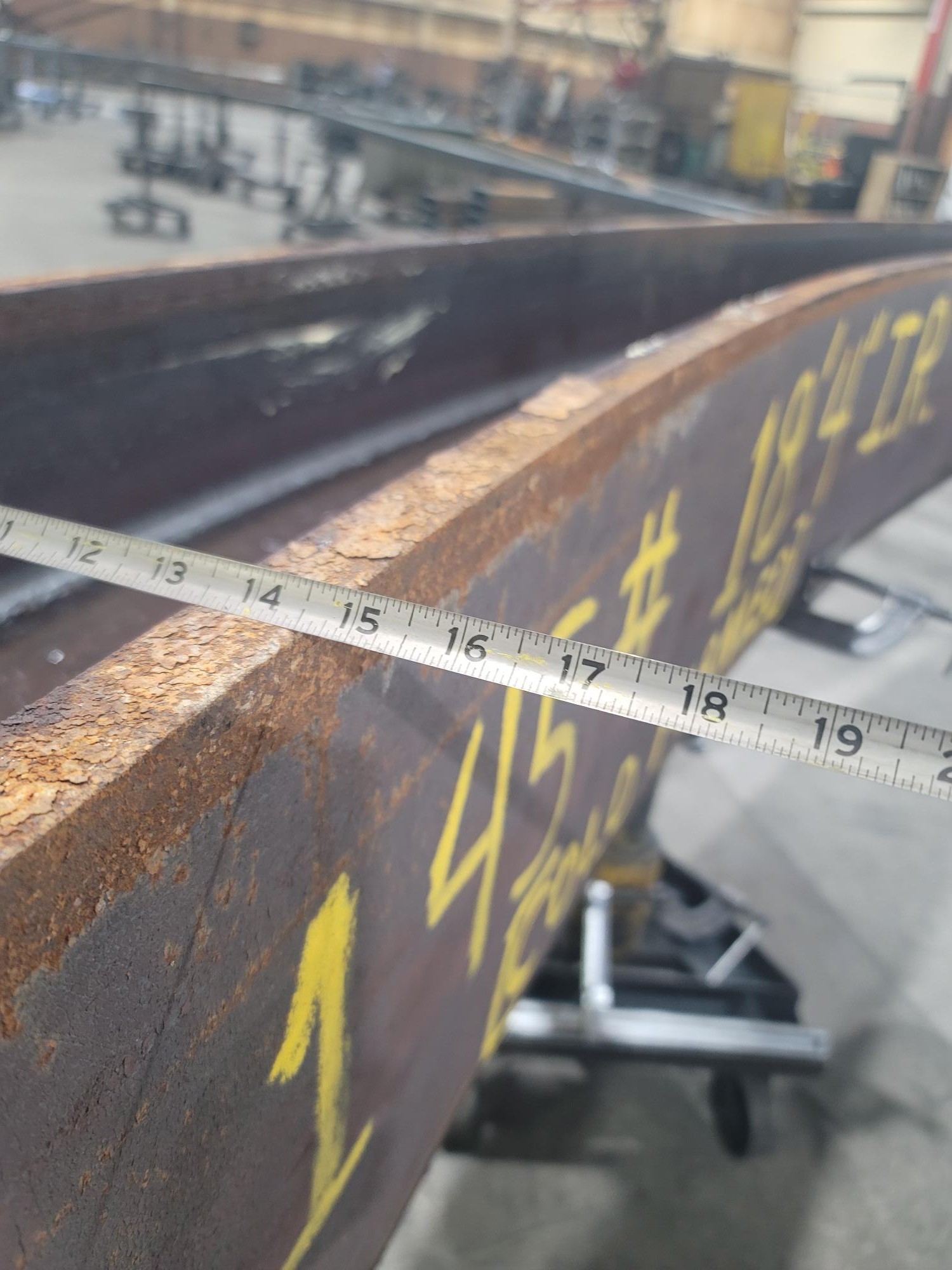

His task was to bend the massive piece to an 18’4” inside radius. Controlling distortion, and maintaining original shape of the section, was paramount. Not easy by any means, though!

Phil’s challenge was tremendous. Curved pieces on this planned stadium’s steel framework would have to line up perfectly with connecting straight pieces. Any unexpected distortion would drive costs skyward … and fast.

Phil got to work, using one of our proprietary pieces of bending equipment. Time wasn’t a concern. Over the course of many hours, he gradually formed the newly-curved monster.

Was it accurate, though? Had the daunting inside radius been achieved?

Indeed it had. Repeated measurements – followed by more measurements, and then some – verified the veracity. It was done. Phil had conquered the beast.

The surrounding photos show his accomplishment, of which he’s rightly proud. We’re proud of him, too!

More so, we’re prepared to bid on this new soccer stadium, and hopefully add it to our impressive repertoire of similar projects. We’re ready, capable and – thanks to “spec bending” – confident of a winning effort!

|

|

|

<<-- Back to News Email to a friend